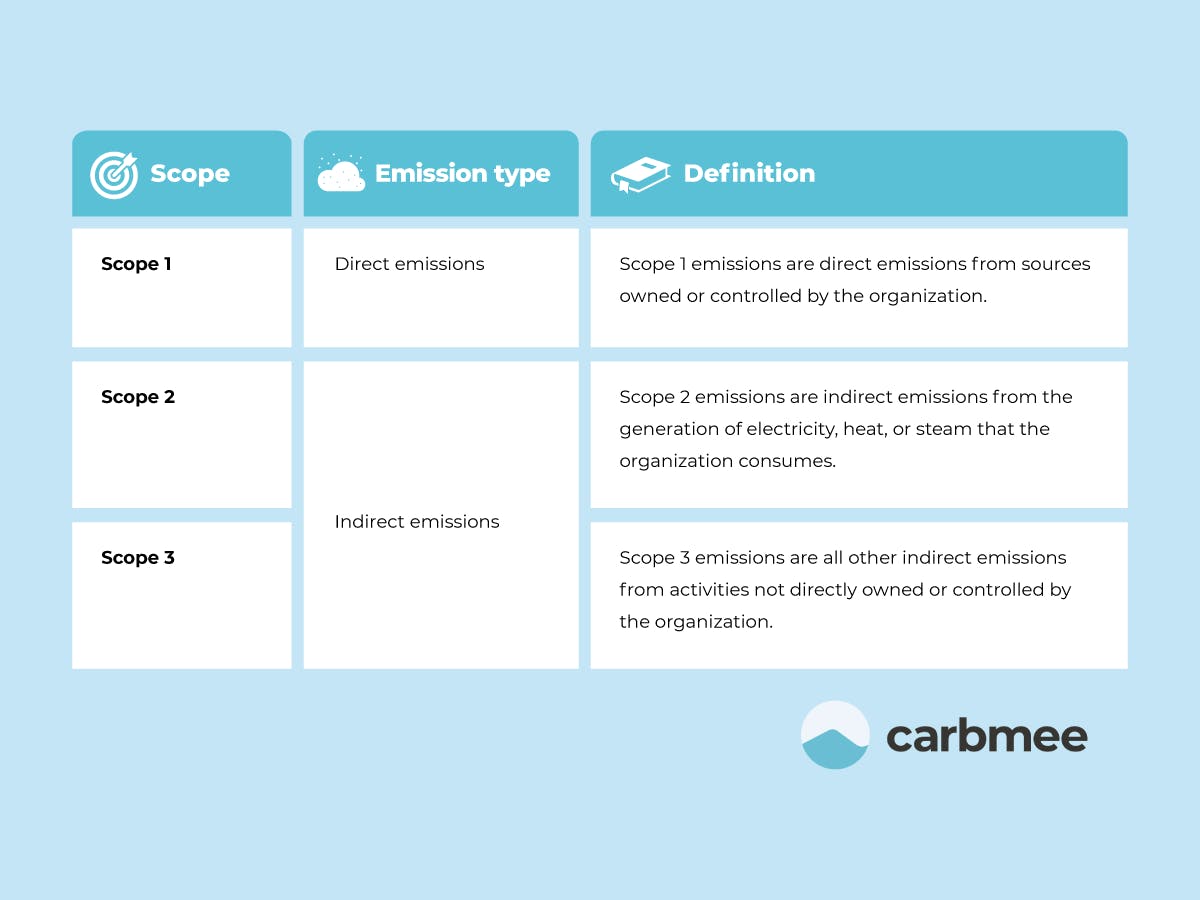

What Are the Three Scopes of GHG Emissions?

The Greenhouse Gas (GHG) Protocol provides the global standardized framework for measuring and managing greenhouse gas emissions. It classifies emissions into three distinct categories, or "scopes," to help organizations account for their direct and indirect environmental impact.

Scope 1: Direct emissions from sources that an organization owns or controls, such as company vehicles and manufacturing facilities.

Scope 2: Indirect emissions from the generation of purchased electricity, steam, heating, or cooling consumed by the company.

Scope 3: All other indirect emissions that occur in a company's value chain, including both upstream and downstream activities.

What Are Scope 3.1 Emissions?

According to the GHG Protocol, Scope 3.1 emissions include all upstream (cradle-to-gate) emissions generated during the production of goods and services purchased by your company. This category is often the largest and most complex part of an organization’s carbon footprint, as it spans the entire supply chain; from the extraction of raw materials to the manufacturing, processing, and transportation of materials and components between suppliers up to your Tier 1 partners.

Why Are Scope 3.1 Emissions Important?

Recognizing the importance of Scope 3.1 emissions is key to aligning sustainability goals with business outcomes.

Significant Portion of Carbon Footprint: For sectors like manufacturing, retail, and consumer goods, Scope 3.1 emissions can represent the vast majority of the total GHG inventory. Addressing this category is not just a matter of compliance; it is essential for any credible net-zero strategy and provides the greatest potential for decarbonization.

Increased Regulatory Pressure: New regulations place a strong emphasis on value chain transparency. The Corporate Sustainability Reporting Directive (CSRD) in Europe and the Carbon Border Adjustment Mechanism (CBAM) require detailed reporting on supply chain emissions. Accurately measuring Scope 3.1 is critical for compliance and avoiding penalties.

Supply Chain Decarbonization Opportunities: By analyzing Scope 3.1 data, you gain deep insights into your supply chain's emission hotspots. This allows you to identify the 20% of suppliers or materials that may be causing 80% of your emissions, enabling you to focus reduction efforts for the highest return on investment.

How Do You Calculate Scope 3.1 Emissions?

These proven best practices will help you calculate Scope 3.1 emissions with precision and achieve measurable results.

Step 1: Select a Calculation Method

Organizations can calculate emissions using either a spend-based or activity-based method, depending on their needs and available data. The spend-based model estimates emissions by multiplying the monetary value of purchases with industry-average emission factors—helpful as a starting point but less precise. In contrast, the activity-based calculation relies on detailed information such as quantity, weight, or volume of goods purchased, combined with specific emission factors, providing far more accurate and actionable insights.

Depending on the chosen approach, you will need to know:

- product-specific GHG emissions originating at the direct supplier level (Tier 1) as well as in the upstream chain (Tier 2 to Tier n),

- quantities for purchased items and components (e.g. the number of units, weight, volume),

- the cost of purchased goods and services,

- activity data at the supplier level, such as proportional energy and fuel consumption, waste, etc.

Step 2: Enrich Primary Data Over Time

Primary data relates to specific activities within a company’s value chain that is provided and validated by the source. It is generally more accurate than secondary data, which reflects industry averages or benchmarks. However, detailed primary data on product-related GHG emissions from Tier 1 suppliers is often unavailable or lacks sufficient quality.

Carbon management is an ongoing process, and companies can start their decarbonization journey with secondary data. It provides a solid foundation that can later be refined with primary data, enabling more targeted reduction strategies.

Step 3: Choose the Right Emission Factors

Identifying the right secondary data sources and emission factors can also be a challenge when calculating your company’s carbon footprint. Emission factors are used to determine GHG emissions based on different types of data, such as:

- purchase spend (e.g. kg CO2e per euro purchase value for a particular product group),

- unit (e.g. kg CO2e per kg weight of a particular good),

- activity data (e.g. kg CO2e per kWh).

The type of emission factors required depends primarily on the calculation method your company chooses.

Step 4: Overcome Inevitable Data Gaps

Initially, many companies may only be able to include a portion of their purchased goods and services in Scope 3.1 emissions calculations.

Consequently, they will need to consider the level of validity when extrapolating the collected emissions data for the remaining purchases for which no data was collected. Similarly, emission factors may not be available for some specific processes, resulting in data gaps that must be filled over time—either by collecting primary data or using suitable proxy data from reliable databases.

Key Strategies for Reducing Scope 3.1 Emissions

Cutting Scope 3.1 emissions isn’t just about knowing your numbers. It’s about driving real change where it matters most: across your supply chain. By integrating sustainability into purchasing and building stronger partnerships with suppliers, you can unlock meaningful reductions and accelerate your path to net zero.

Drive Reduction Through Sustainable Procurement

When assessing and reducing your company’s Scope 3.1 emissions, the procurement team plays a central role as they manage purchase orders and supplier relationships. By embedding sustainability criteria into purchasing decisions, they can prioritize low-carbon suppliers, choose recycled or low-impact materials, and directly influence the company’s environmental footprint at its source.

Foster Collaboration with Supplier Engagement

Net-zero can't be achieved alone.It requires your organization to lead and mobilize stakeholders toward your goals. Directly engaging your suppliers and inviting them to collaborate is an effective way to gain their buy-in and identify your most strategic partners. By working closely with them, you can obtain accurate and validated data to develop actionable insights into how your purchased goods are manufactured and distributed. This is key to differentiating the emissions you produce from those you receive, allowing your teams to plan and execute targeted, high ROI reduction initiatives.

Simplify Scope 3.1 Management with Carbmee

Carbmee helps companies drive their sustainable transformation by applying the 80/20 rule: focusing on the 20% of value chain activities that cause 80% of emissions. With the carbmee EIS™ carbon management platform, you can gain hotspot transparency for Scope 3.1 within days and empower your teams to make bold, data-driven decarbonization decisions.

Key benefits:

Activity-based calculation for optimal transparency: To achieve full Scope 3.1 transparency, carbmee EIS™ uses an activity-based approach built on ecoinvent models, carefully selected for their best fit to the materials or services being analyzed. You can also use a supplier-specific approach, which follows the same methodology but replaces generic data from the database with enriched primary data obtained directly from customers or suppliers. This enables you to calculate emissions more precisely and to plan efficient reduction initiatives.

Collaboration for granularity: The platform’s collaboration feature enables you to engage suppliers directly, helping secure their buy-in and identify your most strategic partners. By inviting them to validate or refine emission factors for materials, energy mix, transportation, and more, your company can significantly increase the granularity of its Scope 3.1 data.

High ROI: By aligning suppliers with your sustainability objectives, applying activity-based carbon accounting, and strengthening data quality through collaboration, you gain the insight and confidence to implement high-impact, cost-effective emission reduction measures.

Ready to turn data into action? Talk to one of our industry experts to discover how carbmee EIS™ can help you achieve Scope 3.1 transparency and accelerate your carbon reduction goals.

Scope 3.1: Frequently Asked Questions

What Is Included in Scope 3.1?

Scope 3.1 includes the cradle-to-gate emissions of all goods and services purchased or acquired by the reporting company in the reporting year. This encompasses raw material extraction, processing, manufacturing, and transportation of products before they reach your company.

Why Are Scope 3.1 Emissions the Hardest to Measure?

Scope 3.1 emissions are challenging to measure because they occur outside a company's direct control. Accurate calculation requires collecting vast amounts of data from a complex, multi-tiered supply chain where information is often unavailable, inconsistent, or of poor quality.

What Is the Difference Between Upstream and Downstream Emissions?

Upstream emissions are indirect emissions related to purchased goods and services, occurring before they reach your company (e.g., Scope 3.1). Downstream emissions are indirect emissions that occur after a product leaves your company's control, such as distribution, customer use, and end-of-life treatment.

How Can a Company Reduce Its Scope 3.1 Emissions?

Companies can reduce Scope 3.1 emissions by engaging directly with suppliers to encourage them to decarbonize, redesigning products to use low-carbon materials, switching to suppliers with lower carbon footprints, and incorporating sustainability criteria into their procurement policies.

What Is the 80/20 Rule for Scope 3 Emissions?

The 80/20 rule, or Pareto principle, suggests that approximately 80% of a company's supply chain emissions often come from just 20% of its suppliers or purchased goods categories. Identifying and focusing decarbonization efforts on these "hotspots" is the most efficient way to achieve significant reductions.